Precious Metals for a Broad Range of Applications

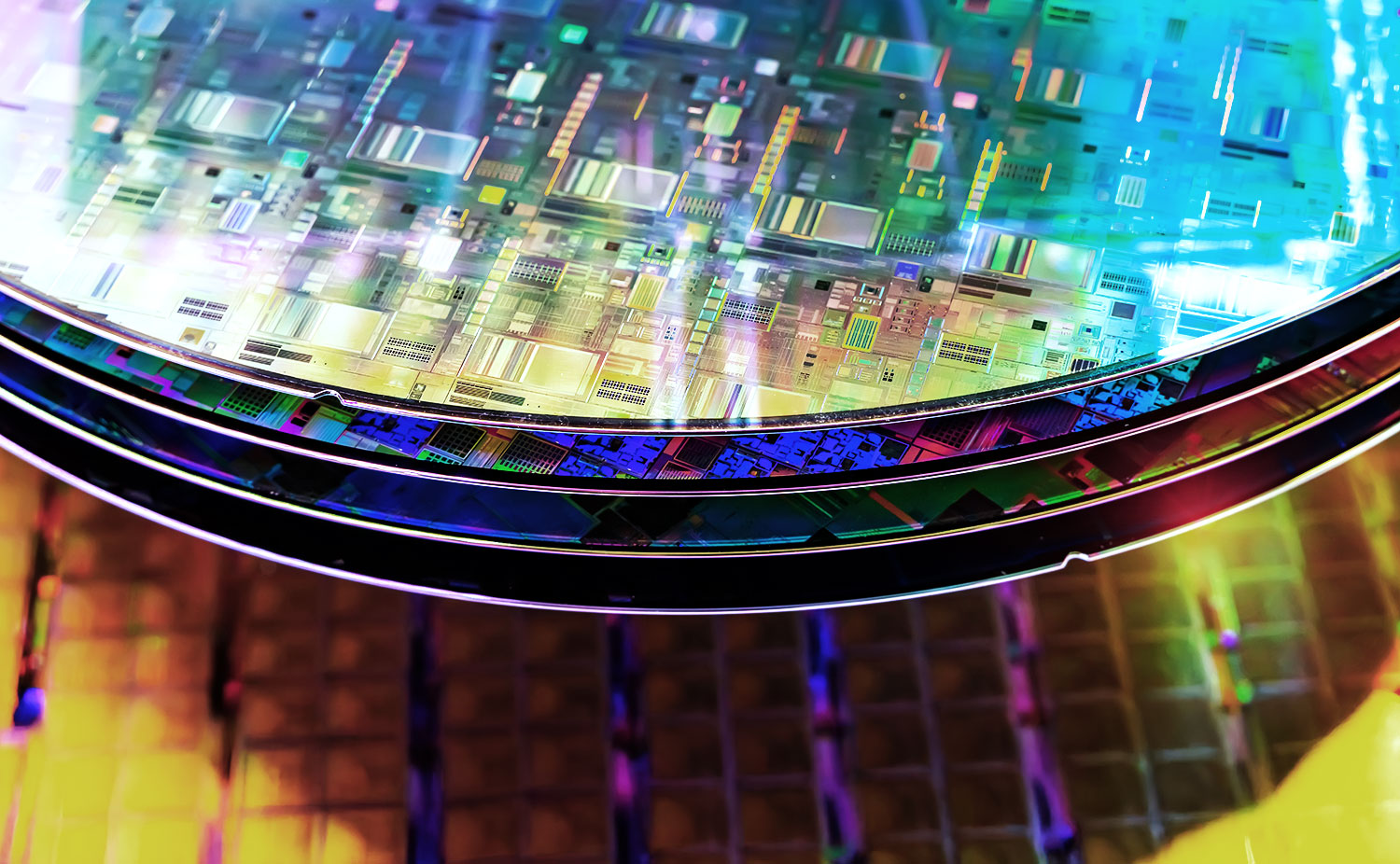

Custom solutions for the semiconductor industry

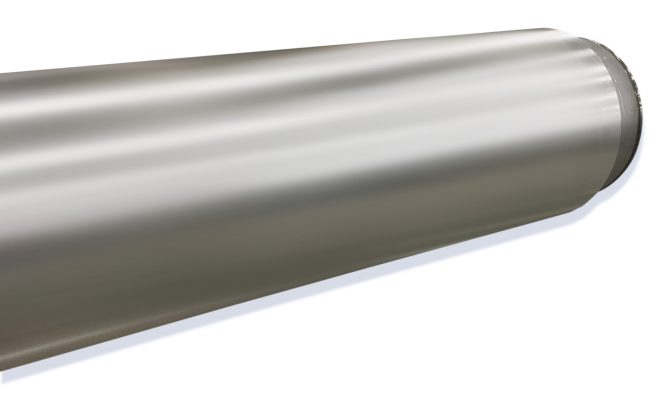

RSC manufactures precious metal and precious metal alloy sputtering targets for broad use in the semiconductor industry.

Target Materials We Produce

- Gold – 4N and 5N Planar Targets

- Silver – 4N and 5N Planar Targets

- Nickel – High Purity Planar Targets

- Palladium – 3N5, 4N Planar Targets

- Platinum – 4N Planar Targets

- Nickel – High Purity Planar Targets

Types of Applications

01

Platinum (Pt) & Palladium (Pd)

Pt, Pd targets can be used in specific products during the wafer fabrication process.

02

NiPt

NiPt targets can be used to create stable silicide thin films in advanced processes.

03

Gold (Au)

Au targets are used particularly in compound semiconductors to form highly conductive and stable ohmic contacts. In backside metallization processes, gold (Au) pads are used for wire bonding. RSC also produces gold wires that can be further drawn to produce gold bonding wire.

04

Nickel (Ni)

High purity nickel targets are also produced by RSC for use in contact layers particularly in compound semiconductors. RSC’s proprietary processing optimizes the pass through flux of the nickel targets to allow optimum magnetron sputtering of this magnetic material.

05

Silver (Ag)

We also produce silver targets (Ag) often used in power semiconductors for backside metallization where very low contact resistances are required.

Collaborate with RSC today!

Delivering what customers want, when they want it.

Whether you’re targeting cost efficiency, grain structure, purity, or other material properties, we tailor our processing to meet your exact specs. With proprietary quality control methods, we ensure each product is free from voids, inclusions, and meets the highest standards of purity and performance.

"*" indicates required fields